VIBRO CIRCULAR MACHINES

Please to introduce ourselves as leading manufacturers of vibrating machine and vibro screens. SIRIRAM & CO. Vibrating circular screens are used either for wet solid-liquid separation or for dry solids classification.

SIRIRAM & CO. Vibrating circular screens is a unitised gyratory screen. It is the largest of its type available today, with three-component multi-place mechanical vibration. It handles wet & dry screening of particles ranging from 10mm down to 400 mesh in size. It gives very high capacity per sq.ft of screening area & consumes minimum energy. The motivation is through a motor with a double extended shaft, fitted at both ends with eccentric weights.

The whole base-unit drive assembly is mounted on a circular base with rugged springs which allows the unit to vibrate freely, and comprises carbon steel base and a motor table, support springs and spring mounts, top and bottom eccentric weights, a lead scale indicator, and a heavy duty motor for operation on 400-440V, 3-Phase 50Hz power supply. The springs prevent transmitted vibration reaching the floor area on which the machine stands. The screen deck assembles and spacing frames are clamps. Screen deck assemblies can be mounted one on top of the other within the screen assembly. Siriram Vibrating Circular screens is suitable for all types of screening operations within these four broad categories.

DRY Separation : This involves separation of different materials on the basis of their particle shape.

DRY Classification : This involves separation of solid particles into precise sized fractions.

Solid-Liquid-Separation : This involves dewatering of solids and clarification of liquids.

Solids Classification : This involves separation of solid-particles into sized fractions in a liquid medium.

We specialise in vibro screens for sugar industry as below:-

1. S.S. Screens filled in Rings

2. Clear Juice Filter Screens

3. Sugar Dust Vibro Screens

4. S.S.Screens for all types of vibrating machines

5. Vibrating Screens for Dry Seeds.

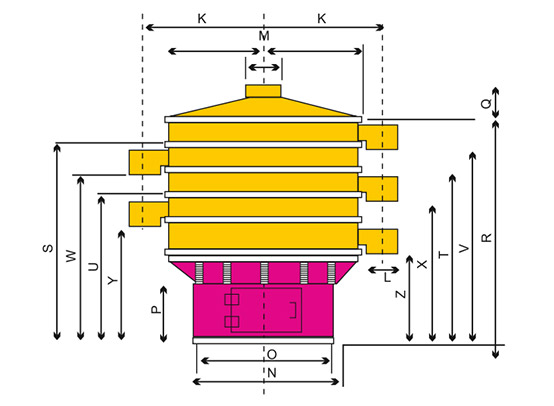

All Dimension in mm.

| MODEL | Z | Y | X | W | V | U | T | S | R | Q | P | O | N | M | L | K | MOTOR H.P. |

| S-600 | 387 | 501 | 616 | 730 | 845 | 635 | 749 | 863 | 978 | 114 | 305 | 451 | 501 | 622 | 152 | 400 | 0.5 |

| S-750 | 387 | 501 | 616 | 730 | 845 | 635 | 749 | 863 | 978 | 114 | 305 | 559 | 635 | 762 | 152 | 490 | 0.5 |

| S-900 | 422 | 587 | 701 | 815 | 929 | 724 | 838 | 952 | 1066 | 140 | 280 | 574 | 680 | 925 | 152 | 571 | 0.5 |

| S-1200 | 565 | 711 | 882 | 1054 | 1225 | 901 | 1073 | 1245 | 1416 | 209 | 381 | 831 | 921 | 1206 | 203 | 743 | 1.5 |

| S-1500 | 565 | 775 | 984 | 1194 | 1403 | 1016 | 1225 | 1435 | 1645 | 171 | 381 | 1010 | 1118 | 1524 | 203 | 914 | 1.5 |

| S-1800 | 568 | 816 | 1063 | 1311 | 1559 | 1083 | 1330 | 1570 | 1825 | 190 | 279 | 1168 | 1264 | 1803 | 203 | 1035 | 2.0/3.0 |