Stainless steel wire mesh / cloth:

Materials :

SS 304 304L 316 316L , Brass , copper, GI. etc..

Character :

acid-resisting, alkali-resisting ,heat-resisting ,corrosion-resisting.

Uses

wire mesh / Cloth is used as sieve mesh for all your Filtration and separation requirements .

SIRIRAM wire mesh factory can produce all kinds of stainless steel woven wire mesh products according to the customers' requirements.

Wire sizes and openings range widely, due to such variety we offers many different weaves. Weave styles are often dictated by the mesh count and wire diameter specifications being used for the product.

Below are descriptions of some common styles we weave :-

Plain Square :-

The most common weave, with the same diameter warp and shute wires woven in a simple over and under pattern. It produces screens with the same mesh count in both directions.

Twill Square :-

Each shute wire typically passes over two warp wires and under two, producing square openings. Twill weave can be made from larger-diameter wires than would be possible in plain square weave to obtain greater strength, density, or corrosion resistance.

Plain Dutch :-

Woven in a plain, over and under pattern. A thinner, smaller diameter shute wire is used; these are driven very close together creating a very tight weave. Dutch weaves do not have a straight-through clear opening as do most Plain weave styles. Instead the weave style creates a tortuous path through which very fine filtration and particle retention can be achieved. Dutch weaves may be specified by “mesh count” or “absolute filter rating.”

Reverse Dutch Weave

The same weave as Plain Dutch except the warp and shute wires are reversed; i.e., the warp wires have a smaller diameter than the shute wires. The larger shute wires are woven closer together than would usually be seen in a Plain Dutch Weave.

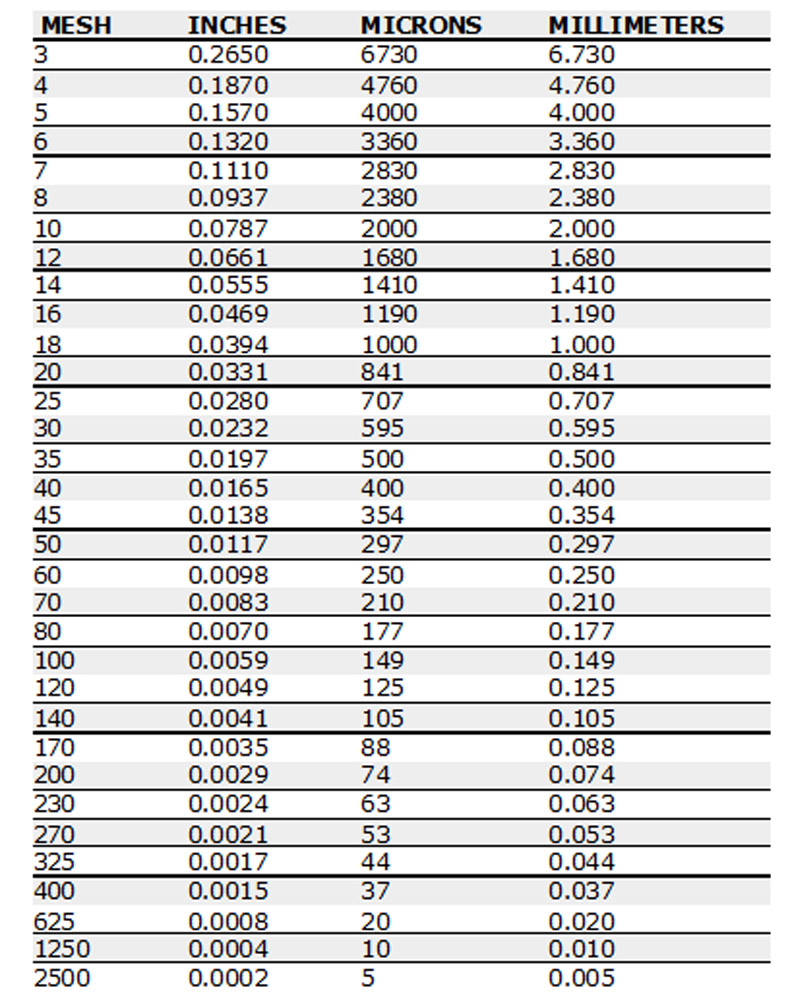

Mesh to micron conversion chart

Dovex:

Wiremesh in square and long mesh finish are crimped and mechanically woven under pre-stressing to a tight compound, gives the mesh a high vibration strength and long service life.

Dovex wiremesh is made of round wire have a completely smooth screen surface. Due to one side smooth surface there is given only little abrasion resistance to the screening material having therewith a favourable influence on the service life of the grid. Through double anchoring at the wire crossings, the wire grid is additionally provided with a tight mesh compound enabling to give with it a constant mesh strength and a precise mesh positioning.

Materials

1. Spring steel

2. Brass

3. Stainless steel

4. Heat-resistant steel